Smooth Roll Crusher - CPC GmbH - Crushing Processing

Comminution of the feed material between the two rolls (fixed and moveable) by mechanical pressure up to 200 to 400 kN, hydraulically induced. Product particle size regulated by

Roll Crushers - ScienceDirect

2016年1月1日 A smooth surfaced roll crusher had a roll diameter of 910 mm. Its suitability to crush an ore at 10.0 t/h was being examined. Preliminary examination showed that the

Long-lasting roller crusher and sizer solutions I FLSmidth

Our roller crushers and sizers are built to last, with strong frames and self-lubrication systems to reduce your maintenance burdens. They offer reliable crushing of materials in

Roll Crusher - an overview ScienceDirect Topics

Roll crushers consist of two or more adjacent rolls placed parallel to each other and rotated in opposite directions. Single roll crushers are also available which rotate a single roll

Roll Crushers - HAZEMAG

Roll crushers with smooth rolls are used for pulverization to generate a product granulometry of ≤ mm. To provide optimum protection for the roll crusher, a hydraulic floating roll

Smooth Roll Crusher - J.C Steele

2016年7月26日 A Smooth Roll Crusher, with both Rollers properly main- tained to a smooth, true surface, and kept set closely at a minimum of about 1 / 16" (1 ,6 mm), will

Howto Size smooth Roll Crushers - 911 Metallurgist

2016年3月2日 smooth Roll Crushers Adam Zanker Smooth roll crushers are widely used as secondary crushers, operating most effectively when set for size re-ductions in a ratio

Smooth roll crusher Manufacturers Suppliers, China smooth roll ...

smooth roll crusher manufacturers/supplier, China smooth roll crusher manufacturer factory list, find best price in Chinese smooth roll crusher manufacturers, suppliers,

A preliminary analysis of smooth roll crushers - ScienceDirect

1980年2月1日 A model is developed to predict the size distribution resulting from any feed size distribution, based on the characteristic breakage parameters of a material between

Modeling of particle breakage in a smooth double roll crusher

2009年2月16日 Each of the five materials was crushed into a Blake type of jaw crusher and the product from the jaw crusher was sieved using 12.7 × 10 3 µm and 6.35 × 10 3 µm size screens. 500 g of retained material was fed to the roll crusher manually approximately in 20 s. The gap between the rolls was 6.35 × 10 − 3 m for all the experiments. B.S ...

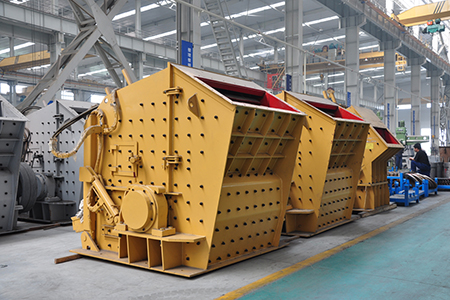

Tooth Roll Crusher: A Versatile Equipment for

2023年2月22日 Tooth roll crusher, also known as double roll crusher, is a versatile equipment used for material reduction in various industries. It consists of two cylindrical rolls that rotate in opposite directions, with

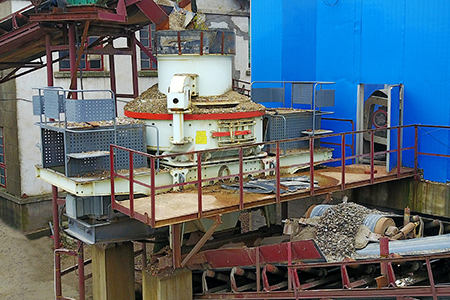

Penjelasan Lengkap Gyratory Crusher yang

2022年12月2日 Tooth Roll Crusher dapat bekerja lebih baik dibandingkan dengan Smooth Roll Crusher, tetapi Tooth Roll Crusher terbatas karena tidak dapat memecah padatan yang kasar. Alat ini bekerja berdasar

McLanahan Double Roll Crushers

The rule of thumb for the Double Roll Crusher’s ratio of reduction is 4:1. The simplified design gives these units excellent reliability and requires very little maintenance. The crushers are designed with built-in tramp relief that allows for the passing of uncrushable objects while remaining in continuous operation and returning to the ...

Smooth Double Roll Crusher – SDRC Series – Mechtech

Overview. Mechtech SDRCs designed for primary, secondary and tertiary crushing are best suited for achieving the reduction ratios of 4:1. It is best suited for producing finer products. SDRCs are widely used and referred for their excellent

Roll Crushers - HAZEMAG

Roll crushers with smooth rolls are used for pulverization to generate a product granulometry of ≤ mm. ... For such tests, a roll crusher is available in HAZEMAG’s own state of the art test facilities, by means of which crusher gap settings, rotor tip speeds, power consumption, crushing teeth geometry and other important parameters can be ...

Modeling of particle breakage in a smooth double roll crusher

2009年2月16日 Experiments were carried out in a smooth double roll crusher and the material used to obtain the empirical relationship were bituminous coal, galena, hematite and quartz. Further the model was verified by applying it on limestone for which HGI was known and π value was obtained using the empirical relationship. The product distribution thus ...

Roller Crusher – Nesans Mining and Automation Private

Nesans CI Series Smooth Roll Crushers are high performance, quaternary stage crushers used for reduction of feed size from 5mm down to 1mm or below. Furthermore, CI Series Smooth Roll Crushers are developed with the ever growing demand for zone 4 M-Sand used in plastering purpose. Equipped with two rolls with smooth surface finish and optimal ...

Smooth Double Roll Crusher - Premur Impex - High

Smooth Double Roll Crusher. Smooth Double Roll Crusher. Application. Secondary and tertiary crushing of soft to hard ore and minerals with a crushing ratio of 2.5:1 max. for hard and abrasive material and 3:1 max for soft and non-abrasive materials. The crushing action take place by surface impact of counter rotating plain rolls.

Roll Crusher with Stable Performance Fote Machinery

5 天之前 (The following roll crusher refers to "smooth roll crusher".) Applications of roll crushers Roll crusher is applied more widely than other crushers because of its small volume and cheap price. With the adjustable discharging system, it can be used flexibly in coarse and fine crushing processes of the industries such as cement, chemical ...

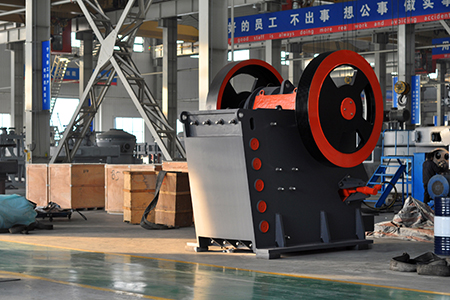

CHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE

2011年12月27日 – Serrated or toothed roll crusher Smooth roll crusher • Two heavy smooth faced roll rotating towards each other at same speed on parallel horizontal axes • Size of the material caught by the rolls depends upon the coefficient of friction between the material and the roll surface • Dp = 0.04R + g Dp – maximum size of particle . R ...

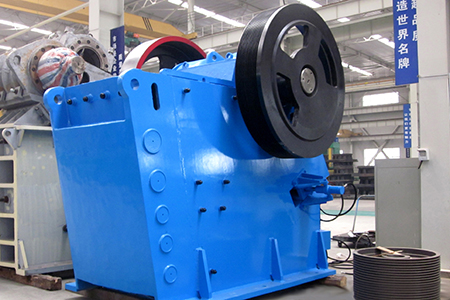

McLanahan Roll Crushers

Since patenting the first Single Roll Crusher in 1894, McLanahan has become an expert and leader in the industry in the design and manufacture of single and two stage Roll Crushers. The selection process for each application is based on extensive equipment knowledge and a wealth of test data developed in our research lab or through on-site testing.

Mid-range rolls crushers – tough on any material - FLSmidth

Essa RC2000 Rolls Crusher – compact and rapid standalone rolls crusher with 2 x 200 mm rolls. Common applications include coal and diamond mining. Essa RC3000 Rolls Crusher – a larger and much more powerful rolls crusher with 2 x 350 mm rolls. A choice of two configurations gives you flexibility for continuous or batch use in laboratory and ...

Roll Crushers - Top 2022 Models - 911 Metallurgist

4 天之前 Progress in Roll-Crushing. BY C. Q. Payne, New York, N. Y. On the right, a Roll Crushers is shown in a sectional elevation of the A-C single-roll crusher while here below is a cutaway view of the machine, with hopper and part of the near side frame removed to show the crushing chamber. The moving elements of the machine consist of the roll, with

New Used Roll Crushers for Sale Rock Crushing

2 天之前 New and Used Roll Crushers for Sale Savona Equipment is a roll crusher supplier worldwide.We can supply new and used belt-driven roll crushers. There are in four designs of roll crushers: single roll crushers, double roll crushers, triple roll crushers, and quad roll crushers.Roll Crushers are built to handle primary, secondary and tertiary stage crushing

Smooth Double Roll Crusher – Persistent Casting

Smooth Double Roll Crusher is used for medium and fine crushing of soft to medium hard material like coal, fertilizer, chalk, clay, limestone, coke, glass etc. It can be also used for tertiary crushing of hard material like iron ore, refractory material. For better nipping of crushing material, the feed size is limited to 45150 mm(max).

Roller Crusher Manufacturer Supplier in Gujarat, India

Roll Crusher. Leading Roller Crusher Manufacturer Supplier in Gujarat, India Roller crushers are made of heavy very hard roll shell surface of alloy steel to crush materials like iron ore, manganese ore, metal slags, emery, glass, quartz, ceramic in granule form or a coarse powder. From roll crusher two stage crushing is possible to get fine powder.

Double roll crusher thyssenkrupp Polysius

Double-Roll-Crushers are used for the crushing or medium-hard rock as well as for sticky and soft materials, i.e. clay, marl, limestone and similar raw materials. Sticky and soft materials are reliably crushed in 2 or 3 stages down to the required product size. Due to the low crushing ration, the thyssenkrupp Double-Roll-Crusher is producing a ...

Double Roll Teethed Roll Crusher - 911 Metallurgist

2016年2月24日 The range of the smooth-face rolls, for example, is from about 400 ft/min for the small 12-in. rolls, to 2000-2200 feet/minute for the heavy-duty 72″ machine. The single-roll crusher has a tip speed of 400-450 ft/min while the 6- x 7-ft teethed roll crusher has a normal, no-load, surfaces speed of just under 3500 ft/min.